T Slot Camera Mount

Posted By admin On 26/07/22The 3/8-16 standard is in wide use today in photography, though — just not for camera mounts. It's common for lighting gear, including lighting stands and mounts. I have some Manfrotto gear with the reversible studs — basically, camera mount one side, lighting equipment the other way.

Foveal Fine-adjustment 2-axis Mounts

with Metric Mounting Slots

→ DISCONTINUED ←

Only a few left. Discounted Price. See Prices and Delivery

Replaced by Customizable 2-Axis Fine-Adjustment Camera Mount

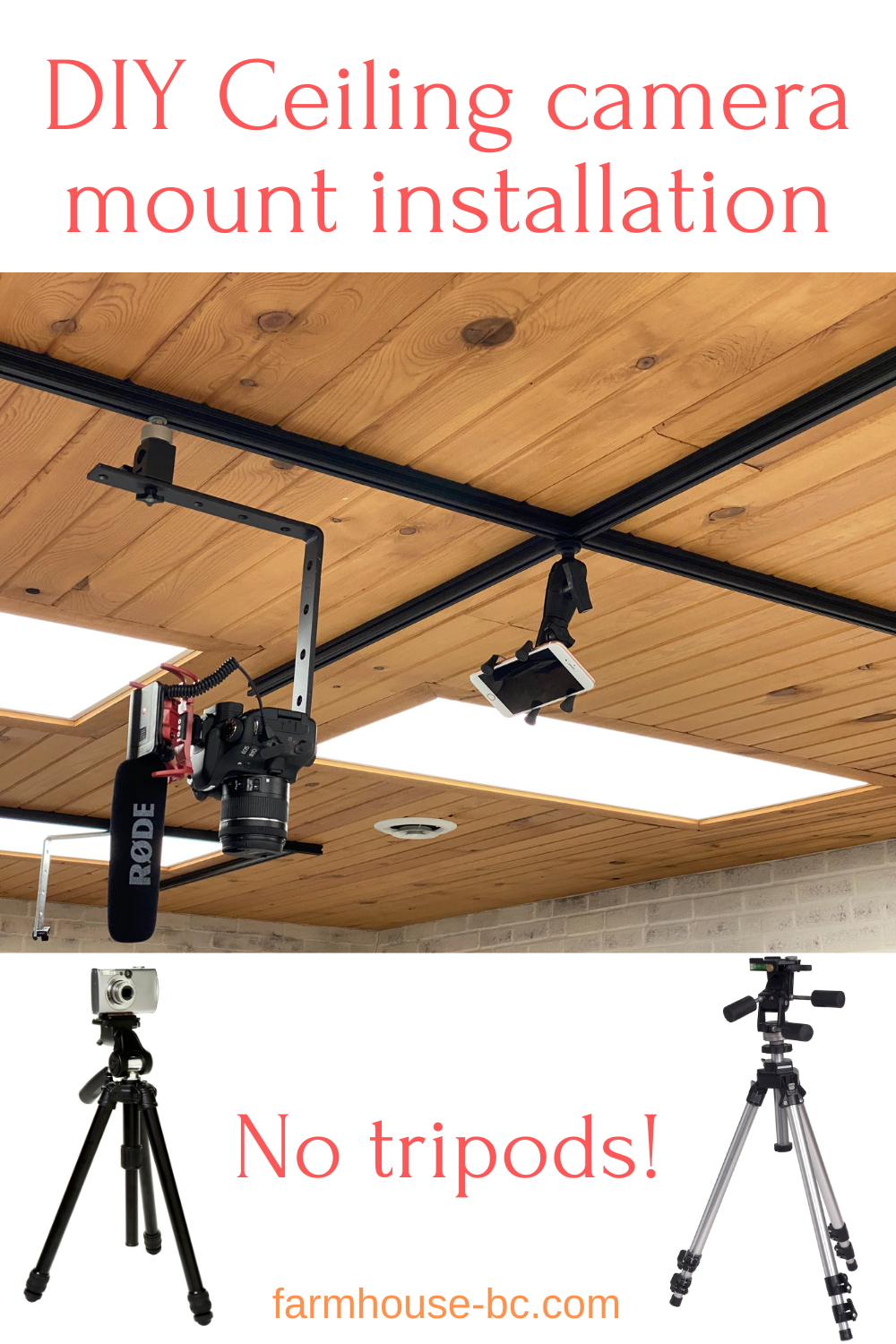

Mount these bull's eye levels to workstation and table frames made of T-slotted framing for easy leveling in all directions on the horizontal plane. T-Slotted Framing Lighting Illuminate workstations. Mount these bull's eye levels to workstation and table frames made of T-slotted framing for easy leveling in all directions on the horizontal plane. T-Slotted Framing Locks and Latches Secure doors and windows made of T-slotted.

| On this page: | MotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

| Many machine vision cameras have threaded mounting holes that take metric screws, usually ranging in size from M3 to M6. Foveal Mounts FM (Fine-adjustment Mounts) now come with general purpose slot patterns to accommodate many of those manufacturers, including many (not all) models made by Allied Vision, Basler, Cognex, Edmund Optics, IDS, JAI, Keyence, Manta, Point Grey, Sentech, Teledyne Dalsa, PixeLINK, and other machine vision brands. As with all FM mounts, they also provide

|

| Fine-adjustment Mounts for cameras using 3mm, 4mm, 5mm and 6mm metric mounting screws. |

| Click to enlarge pictures and drawings. |

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Motivation

The originalFoveal 2-Axis Fine_Adjustment Camera Mounts,modelswere designed a decade ago to match commonmachine vision camera mounting configurations.

T Slot Camera Mounts

But we realized that there are now lots of machine vision cameras out therethat use metric screws,but the hole patterns are not at all standardized.

Now we offer these mounts with slot patterns that will accommodatemany different hole spacings,and even 3-screw triangular patterns.

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Featuresin common with all FM models

The 2-Axis Fine-Adjustment Camera Mountsmay be supported with the base down or the base up. In either position, the plate the camera attaches to can beeither below or above the camera.

When coarse adjustments are unlocked,there is sufficient friction to hold the camera in position. Coarse position can be set by hand.

Fine adjustments are made using a hex wrench,allowing for extremely fine positioning.

Independent adjustment of each axismeans each adjustment does not affect the other.

All adjustments and locking are made with a single 3/32 inch hex wrench. Reconfiguration is done with a 9/64 inch hex wrench.

Once the mount is locked, the camera does not move.

And the mounts are highly reconfigurable.

See theFine-adjustment Mountpage for other, non-metric models.

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Examples

Only a few left. Discounted Price. See Prices and Delivery

| Cognex |

Also see our other mounts suitable for other Cognex cameras: |

| → DISCONTINUED ← Only a few left. Discounted Price. See Prices and Delivery IDS |

| → DISCONTINUED ← Only a few left. Discounted Price. See Prices and Delivery Basler |

| → DISCONTINUED ← Only a few left. Discounted Price. See Prices and Delivery Keyence |

| → DISCONTINUED ← Only a few left. Discounted Price. See Prices and Delivery Teledyne Dalsa |

| Examples of Fine-adjustment Mounts for cameras using 3mm, 4mm and 5mm metric mounting screws. |

| Click to enlarge pictures and drawings. |

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Options

| Finger Adjustment Knobs (FAK) Option Prices and Delivery | |

|---|---|

| When the need is not set it and forget it but instead the mount frequently needs to be finely adjusted, we offer knobs for the fine position adjustment screws. | |

| Lock Nuts and Lock Washers (LNLW) Option Prices and Delivery | |

| If your mount will be subjected to high vibration, extra lock nuts and lock washers might help. LNLW Installation Manual | |

| Extra Fine Adjustment (EFA) with lock nuts Option Prices and Delivery | |

| The normal change in the Pan or Tilt angle is bit more than 2 degrees per turn of the position screws. Should you need a finer adjustment, this option provides slightly less than 1 degree per turn. While shown here with the PTD option (below), EFA and PTD are separate options. EFA Manual | |

| Pan and Tilt Protractor Dials (PTD) Option Prices and Delivery | |

| We offer mounts with Protractor Dials on both the Pan and Tilt Axes so the angles can be read out. See the complete description at Foveal Mounts with Pan and Tilt Protractor Dials. |

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

CAD File Downloads

STEP format| FM3mm_2a-LMP.stp.zip | FM3mm_2a-RMP.stp.zip FM4mm_2a-RMP.stp.zip FM5mm_2a-RMP.stp.zip FM6mm_2a-RMP.stp.zip | FM3mm_2a-SMP.stp.zip |

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Mounting Plate Options

There are four mounting plate options for the FM mounts.| no mounting plate | The pan pivot has two 8-32 threaded holes in it. |

| -SMP3 | Square Mounting Plate suitable for general mounting to flat surfaces. |

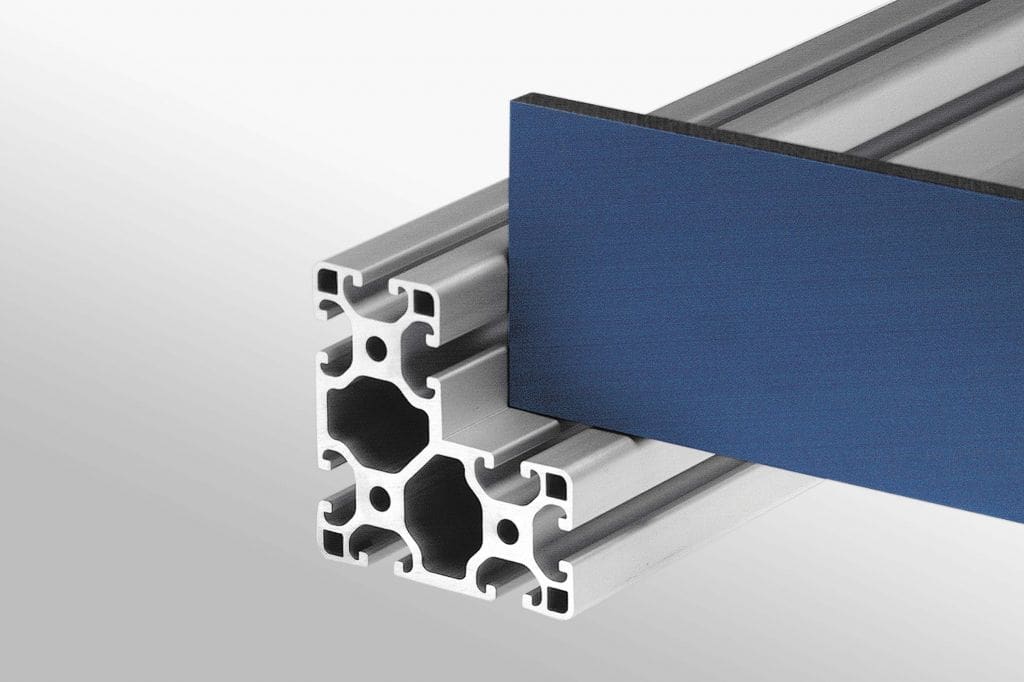

| -RMP | Rectangular Mounting Plate for general mounting or T-Slot framing systems. † |

| -LMP | L-bracket Mounting Plate specifically for T-Slot framing systems. † |

| 3 x 3 inch Square Mounting Plate -SMP3 | 5 x 2 inch Rectangular Mounting Plate -RMP | L-bracket Mounting Plate -LMP | ||||

| FM1_2a-RMP mounted on T-Slot frame | FM1_2a-LMP mounted on T-Slot frame | |||||

| Click to enlarge pictures and drawings. | ||||||

| See CAD files Above | ||||||

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Prices and Delivery

United States dollarsFOB New Jersey, United States

6.625% Sales Tax to customers in New Jersey

Call 973 822-2085

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Camera Mounting Alternatives

Adjusting camera mounts can become tedious in tight or inconvenientspaces. We have made the Fine Mounts customer-configurable,so alternative placements of the adjustment screws are possible.| For example,it may be more convenient to have the pan and tiltcoarse- and fine-adjustment screwsavailable from the back of the mount.As this drawing shows, they can be moved.(Moving the pan and tilt screws are independent operations.We do not know why one would want to, but they can be on opposite sides.) |

| Note that these mounts can be configured with the tilt-axis L-bracket raisedabove the pivot. In this position, a small camera can be hung above the pan axis. Also, the tilt axis locks can be repositioned so the tilt L-bracket hangsoutside the pan-axis base.This can accommodate larger cameras anda wider selection of tilt positions. |

| Click to enlarge pictures and drawings. |

| Here are some examples with small- and medium-sized cameras. |

| Note also that there is an alternate pivot point on the tilt L-bracket,offset 0.5 inch. In this position, even larger cameras can be accommodated. |

| Click to enlarge pictures and drawings. |

| Here are some examples with medium- and large-sized cameras,and examples where the camera needs to be lifted a well above the base of themount. |

| Also, many cameras have mounting screws on top of the case,which means they can be hung from the top directly. |

| Click to enlarge pictures and drawings. |

| One customer needed to mount the camera from the rear. |

| And there are a few cameras where the mounting screw is on the side. The pan adjustment, which normally changes the pan angle now changes tilt,and the former tilt adjustment changes the pan angle. |

| Click to enlarge pictures and drawings. |

If you need to verify a particular configuration, please contact us.

For a more robust,three axis mount that features fine adjustment and lockingof the pan, tilt, and roll axes, see theFoveal 3-Axis Rigid Camera Mount.

| On this page: | TopMotivationFeaturesExamplesOptionsCAD File DownloadsMounting Plate OptionsPrices and DeliveryCamera Mounting AlternativesContact |

Contact

For information on purchasing Foveal 2-Axis Fine-adjustment Mountsplease contact us ...

Foveal 2-Axis Fine-adjustment Mountsplease contact us ... By e-mail at

info@Foveal.com

Or call

Foveal Systems

+1 973 822-2085

Copyright © 2000 - 2020 Foveal Systems, LLC. All rights reserved. |

www.FovealMounts.com/MetricMounts.html 2020/12/15 21:26:52 9.32

| Type | screw |

|---|---|

| External diameter | 42 mm |

| Flange | 55 mm |

| Connectors | None |

The T-mount is a standard lens mount for cameras and other optical assemblies. The usual T-mount is a screw mount using a male 42×0.75 (42 mm diameter, 0.75 mm thread pitch) metric thread on the lens with a flange focal distance of 55 mm and a mating female 42mm thread on a camera adapter or other optical component. This thread form is referred to as T-thread. (This should not be confused with the M42 lens mount which is also 42 mm diameter, but has a 1 mm thread pitch. The T-thread is sometimes described as 'M42x0.75,' which is the usual manner in which to describe a metric thread.)

The 'T' is said to stand for Tamron or Taisei, a Japanese manufacturer that released in 1957 the first of a line of aftermarket camera lenses that fit 35 mm SLR cameras built by various manufacturers using their universal T-mount. On the first model, the mini T-mount used a M37×0.75 thread; Tamron's canonical M42×0.75 T-thread didn't appear on the market until about 1962. The company referred to it variously as a T-mount, T-thread, T-adapter, or a T-400, but not as a T-2, which is simply the name that Soligor used for its version of the T-adapter. The proprietary lens mount of each camera manufacturer was adapted to the T-mount thread with a simple adapter. Thus a retailer could stock a small number of expensive lenses that would fit a large number of camera brands using a selection of inexpensive adapters.

Some T-mount lenses accept a T-adapter that lacks its threaded inner ring, and simply slides onto the T-mount lens. It is secured only by 3 set screws that match a channel on the lens barrel, such that the barrel is not deformed by the set screws and the adapter can therefore be removed with no damage.

As a common mechanical interface, the T-mount allows components of various manufacturers to be interchanged and assembled. The T-mount is a solely mechanical specification. Electrical or mechanical connections (such as for autofocus) are generally not provided, although Sigma's YS Mount featured an automatic diaphragm coupling.

Besides cameras, T-mounts are used in optical breadboard prototyping components as well as telescope and microscope attachments. The T-mount is also a standard way to mount a camera to a microscope to photograph pathological specimen slides or to a 1.25″ telescope eyepiece.

Adapters[edit]

Because the T-mount lenses have a long flange distance of 55 mm and most 35 mm cameras have shorter flange distances, a simple mechanical adapter called T-Ring is needed to adapt a T-mount lens to any camera body without optical correction to achieve its closest focus distance. An adapter ring has a female M42×0.75 metric thread on one side and a corresponding lens mount of the camera body on the other side. A T-adapter consists of an inner ring with T-mount thread and an external ring with corresponding lens mount. The T-ring and the T-2 ring are identical to each other. Both of them have the inner and outer ring. The two rings (inner and outer) are held together by 3 peripheral screws on the external ring. Loosening these screws allows rotation between the lens and the camera body. This is especially useful when the camera body is attached to telescopes or microscopes.

Standard T-rings usually have the same external diameter of their inner ring because some T-mount lenses have their inner ring built onto the flange, thus the external ring of the T-adapter can be directly attached, as described above.

Since some DSLRs won't meter without electronic lens data, some adapters are now sold fitted with a Dandelion chip which can be programmed to identify the focal length and aperture limits and enable metering and in some cases focal confirmation.[1]

The thickness of the external ring on an adapter is equal to the difference of the flange distance between the T-mount and the corresponding lens mount in order to achieve infinity focus. Other large format camera lenses have a flange distance longer than 55 mm. They can be attached to smaller format cameras with a combination of corresponding lens-to-T-mount-adapter and a T-Ring.

See also[edit]

References[edit]

- ^Advertisement for T-mount with Dandelion chip accessed 5 October 2015

T Slot Camera Mounting Brackets

External links[edit]

Camera Lens Mount

- Making Digital Camera Microscope Adapters. Various examples and machining details of custom-made T-mount adapters.